Energytek ® Energytek Corporation

Activated Carbon Fiber Solvent Recovery

Activated Carbon Fiber Solvent Recovery

The activated carbon solvent recovery device utilizes the advantages of high-efficiency adsorption material – activated carbon fiber (ACF) with strong adsorption capacity and fast adsorption speed to recover organic solvents.

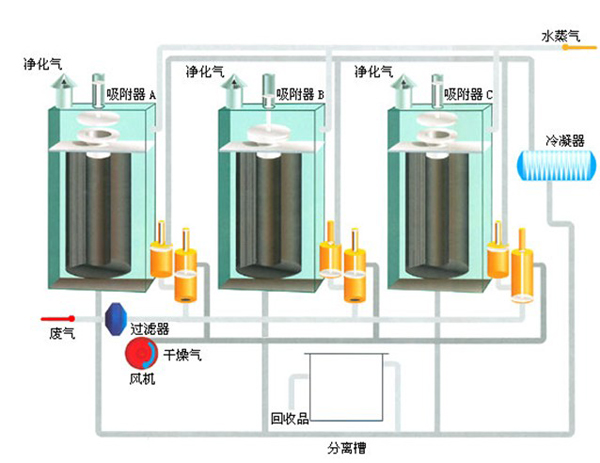

A typical device consists of a blower, an air filter, three adsorption and desorption tanks, a switching valve, a condenser and a separator.

Desorption with water vapor. Through the switching of the valve, the adsorption and desorption of the solvent in the three adsorption and desorption tanks are realized.

The desorbed solvent and water vapor enter the condenser for condensation, and the pure solvent can be obtained after liquid separation.

The activated carbon fiber organic waste gas recovery device is composed of three adsorbers together to form a pipeline system, which can be switched during operation.

When adsorber A is adsorbed, adsorber B is desorbed, and adsorber C is cooled and regenerated.

When the organic waste gas enters the adsorber, the organic matter in it is adsorbed after passing through the activated carbon fiber felt, and the purified gas is discharged from the top of the adsorber.

The three adsorbers A, B and C are switched alternately.

The system uses steam as the desorbent. The desorption steam enters from the top of the adsorber, passes through the activated carbon fiber felt, and desorbs the adsorbed and concentrated organic matter and brings it into the condenser.

After condensation, the mixture of organic matter and water vapor is condensed and flows into the stratification tank.

Sedimentation separation to achieve the purpose of recovering organic matter.

The separated water is discharged to the factory chemical sewage system for centralized treatment and then discharged.

All the action switching during the system operation is completed by the automatic control system.

Device features:

"Activated carbon fiber organic waste gas adsorption and desorption recovery device" is a fixed circulation adsorption bed device, which uses activated carbon fiber with excellent adsorption and desorption properties for adsorption and recovery of organic waste gas.

The technological process is simple, the operation is convenient, the degree of automation is high, and it is controlled by PLC.

The adsorption capacity is large and the adsorption speed is fast.

High adsorption efficiency and high recovery rate.

The equipment is compact in structure and occupies a small area.

It has stable safety performance and is suitable for flammable and explosive places.

The performance is stable, the equipment operating environment is normal pressure, the energy consumption is small, and the operating cost is low.

The equipment has large operation flexibility and can withstand higher fluctuations in temperature, pressure, air volume and concentration.

The investment return period is short, and the investment cost can usually be recovered in a short period of time.

The service life of the equipment is more than 10 years, and the replacement cycle of activated carbon fiber is about 1~2 years, which is related to the concentration of exhaust gas.

Scope of application:

"Activated carbon fiber organic waste gas adsorption and recovery device" can be widely used in chemical industry, petrochemical industry, coating, medicine, pesticide, photosensitive material, rubber, plastic, artificial leather, coating, tanker, printing and other industries. Recycle.

The recovered substances are:

Hydrocarbons (benzene, toluene, xylene, trimethylbenzene, n-hexane, cyclohexane, etc.)

Halogenated hydrocarbons (dichloromethane, chloroform, trichloroethylene, methyl bromide, carbon tetrachloride, etc.)

Aldehydes (acetone, cyclohexanone, formaldehyde, acetaldehyde, furfural, etc.)

Esters (ethyl acetate, butyl acetate, etc.)

Ethers (methyl ether, ethyl ether, methyl ethyl ether, etc.)

Alcohols (methanol, ethanol, isopropanol, butanol, etc.)

Monomers for polymerization (vinyl chloride, etc.)

Activated carbon fiber for organic waste gas solvent recovery:

Product Specifications:

Specific Surface Area (m2/g): BET1300, BET1500

Tensile strength (N): ≥25 (the largest domestic tensile strength)

Thickness (mm): 3~4

Benzene adsorption rate (%): 37~45

product advantages:

①ACF has a large adsorption capacity, which is several to ten times that of GAC.

② The adsorption speed is fast, very fast in the gas phase, and the adsorption equilibrium can also be achieved in the liquid phase, and the adsorption rate is ten to one hundred times that of GAC.

③Easy regeneration and fast desorption, 10-30 minutes with steam or hot air at 120~150℃.

④Good heat resistance.

⑤Acid and alkali resistant, with good electrical conductivity and chemical stability.

⑥ Less ash.

⑦Good formability and easy processing.