Energytek ® Energytek Corporation

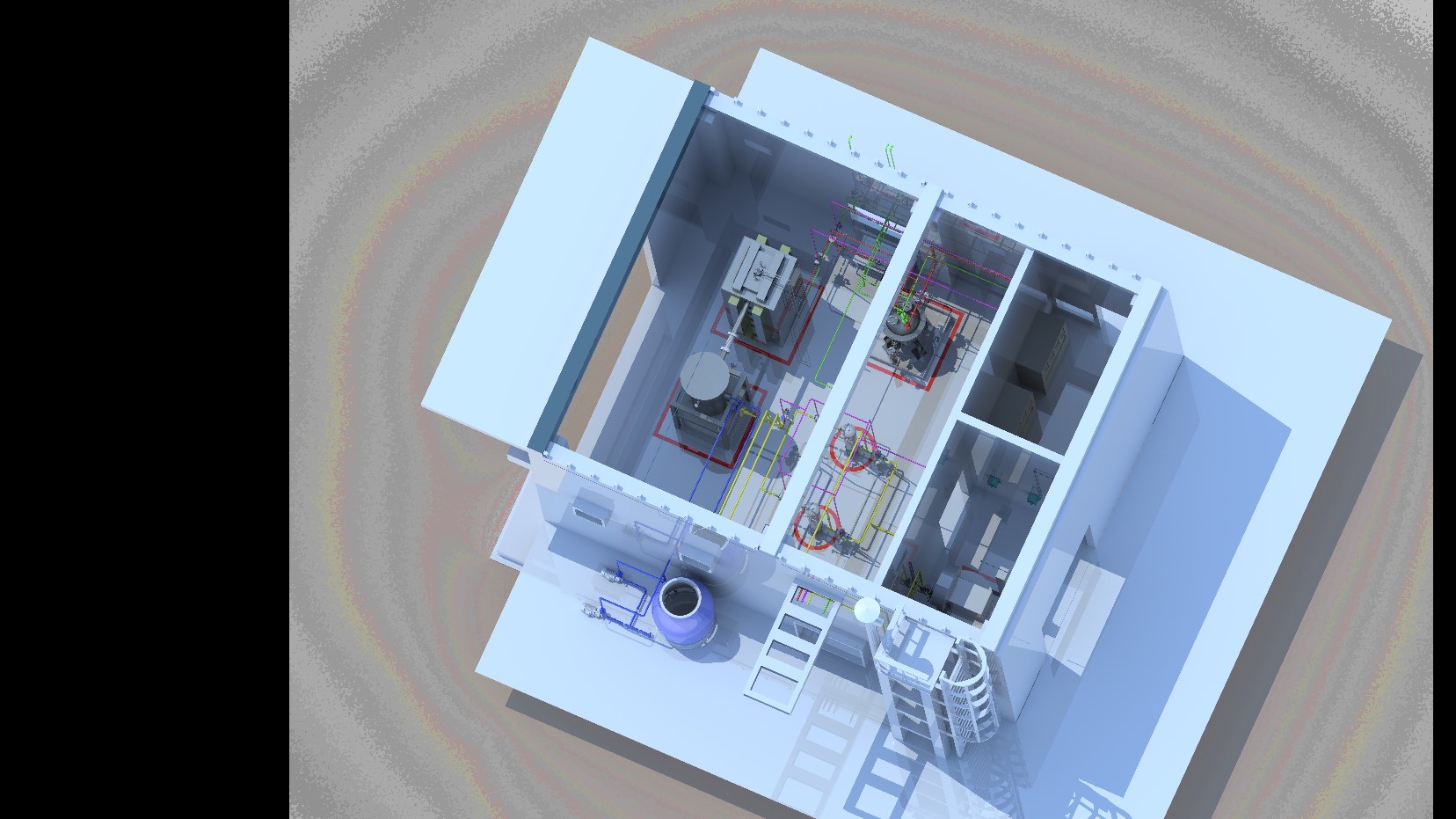

The Organic Waste Fuelization System (FWOSS)

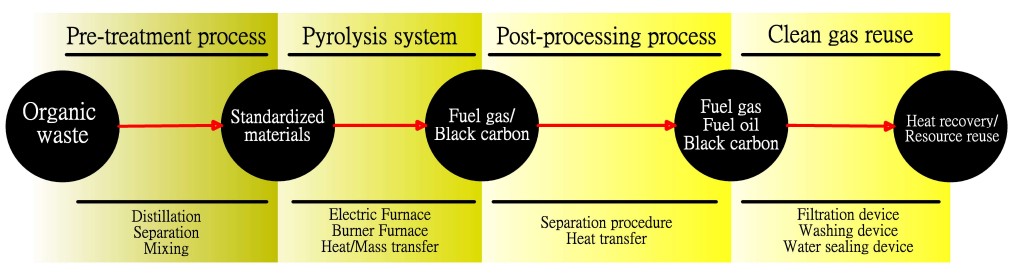

Specifically designed for organic waste generated in traditional chemical and semiconductor manufacturing processes. Through a high-temperature decomposition process, it breaks down high carbon chain molecules into smaller ones. This system can handle various targeted waste, including waste plastics (such as polarizers, municipal solid waste, or secondary products generated in the process), organic waste solvents (such as PGMEA, IPA, MEK, acetone, etc., commonly used cleaning solvents), and sludge.

The process is especially suitable for difficult-to-recycle solvents or reprocessing materials, this system is highly efficient. After high-temperature treatment, the gas components in organic waste mainly consist of methane (CH4), carbon monoxide (CO), and trace amounts of carbon dioxide (CO2). After undergoing processes such as heat exchange and air purification, these produced gases can serve as auxiliary fuels for combustion devices (such as burners, generators, or heat storage circulating boilers). This not only recovers thermal energy but also significantly reduces carbon emissions, achieving the benefits of energy conservation and emission reduction.

Operation Principle of Organic Solid Waste Thermal Pyrolysis Reaction Equipment:

For solid waste, the preprocessing equipment needs to undergo crushing and sorting to an average diameter of 50 to 100 mm before being transported to the pyrolysis reactor. The primary targets can include solid waste such as discarded plastics (e.g., polarizers, municipal solid waste, or secondary products generated in the process), lithium batteries, or sludge. The operating temperature typically ranges between 450 to 650 degrees Celsius. Using lithium batteries as an example, solid waste generally contains about 5 to 10% moisture (or acid solution), and the mix of organic/inorganic substances can range from 30 to 90% of the total ratio, depending on the specific waste composition. After treatment in the thermal pyrolysis equipment, the organic matter removal rate reaches 85% to 90%, with the remaining 10% to 15% residual carbon usable as an additive or for subsequent applications through activation in an activated carbon furnace. If the composition of solid waste is of a polymer nature (such as PP, PS, PE), the recovered fuel oil ratio from the condensed oil and gas after pyrolysis may reach around 20 to 40%, with the remaining output consisting of approximately 10 to 15% combustible gas and leaving behind about 40 to 50% residual carbon.

|

Batch solid waste pyrolysis system

|

|

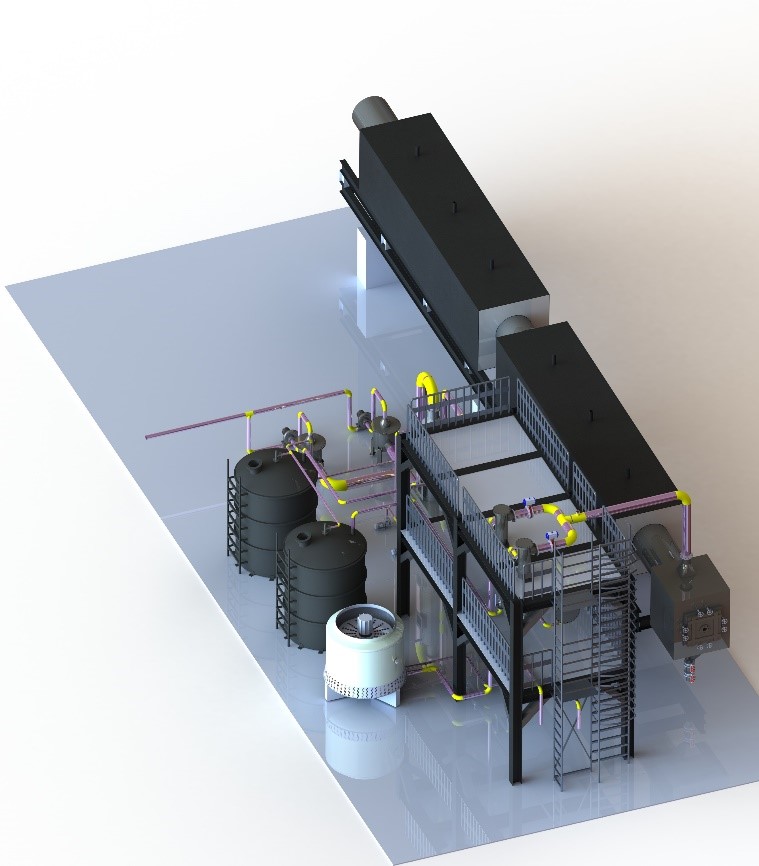

Continuous solid waste pyrolysis system(rotary kiln)

|

Operation Principle of Organic Solvent Thermal Pyrolysis Reaction Equipment:

For liquid waste, the system utilizes a high-temperature thermal catalytic treatment method with an operational temperature range of 450 to 900 degrees, utilizing an inert gas under positive pressure or oxygen-deficient conditions to convert challenging-to-recover organic liquid waste into combustible gases with high calorific value and low hazard. The specific design process of the equipment is customized based on the properties of different solvent waste and subsequent process requirements, primarily assessing integrated solutions according to variations in the solvent's boiling point and the decomposition rate of cracking gases.

Organic solvents, including PGMEA, IPA, MEK, acetone, widely used cleaning solvents, or by-products from chemical plant reactions, can generate combustible gases (with a calorific value ranging approximately from 6000 to 9000 kcal/m3) and carbon black after undergoing thermal treatment processes. In typical operating conditions, the solvent removal efficiency surpasses 99.9%, allowing for the reclamation of approximately 80% to 90% of combustible gases. These gases can be effectively employed for on-site combustion to serve as a source of steam or as auxiliary fuel.

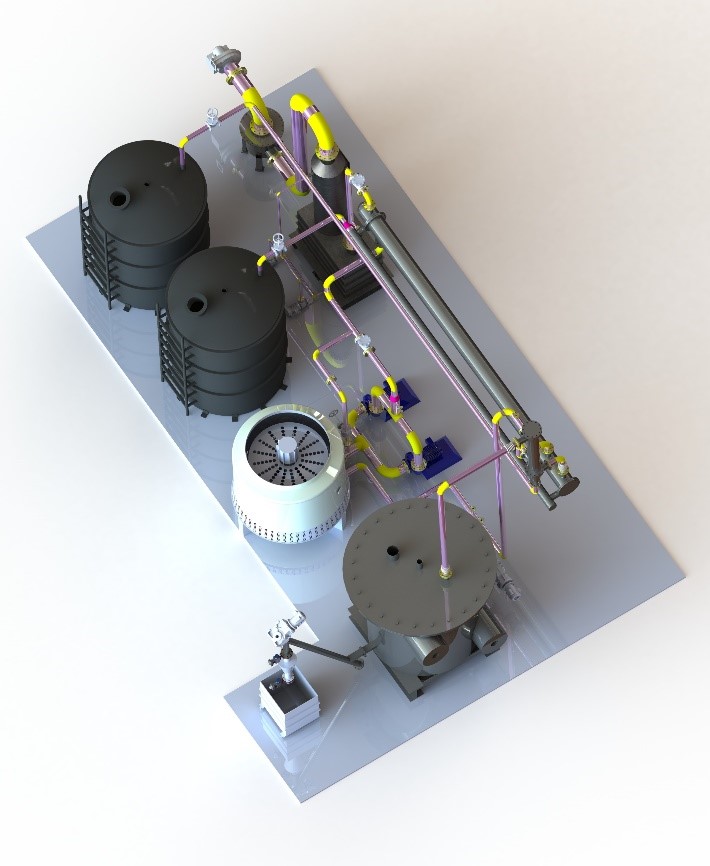

Continuous solvent waste pyrolysis system

Continuous solvent

waste pyrolysis furnace and cyclone-Heat Exchanger