Energytek ® Energytek Corporation

At present, there are three main kiln body structures in rotary kiln:

[1] Rotary kilns with internal heating of kiln tube:

Application:

Sludge drying and sintering; thermal desorption of soil containing mercury/pesticides/oil/dioxin and solvents, waste incineration rotary kiln

Temperature range: 300~1400℃

Fuel: Gas/Diesel oil/Heavy oil

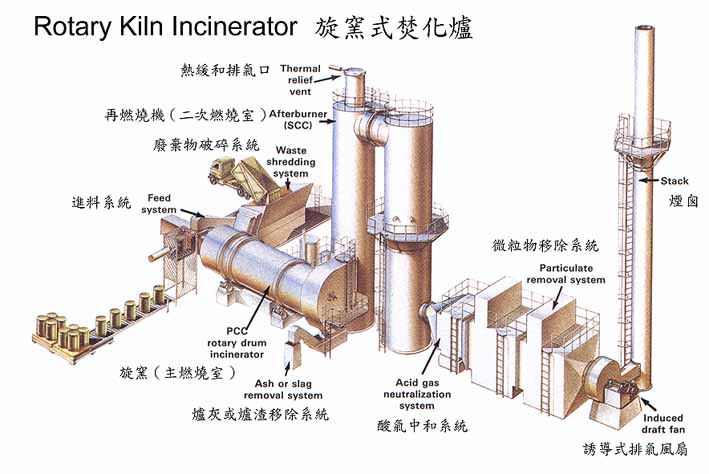

Rotary Kiln Type Waste Incinerator - Currently in the development of solid or liquid waste treatment technology, the most common and advanced incinerator system, with RTO secondary waste gas incinerator, can achieve maximum energy saving.

[2] Rotary kiln with external heating of kiln tube:

Application: For drying, calcination and oxidation of various carbonates / oxides, for example copper oxide / zinc oxide / nickel oxide / iron oxide / cobalt oxide / tungsten oxide / zinc carbonate / copper carbonate / nickel carbonate, etc.

Temperature range: 200~1090℃

Fuel: Electrical Heat /Gas

Kiln tube material: SUS316L, SUS310S, Inconel 601

[3] Rotary kiln with external heating of kiln tube & internal ceramic tube:

Application: Various special materials are calcined, and applications that cannot react with metals, such as lithium / lithium iron phosphate battery materials / graphene, etc.

Internal ceramic tube material: High purity alumina/Graphite

Kiln tube material: SUS316L, SUS310S, Inconel 601

Temperature range: 300~1090℃

Fuel: Electrical Heat

.jpg)

.jpg)

.jpg)